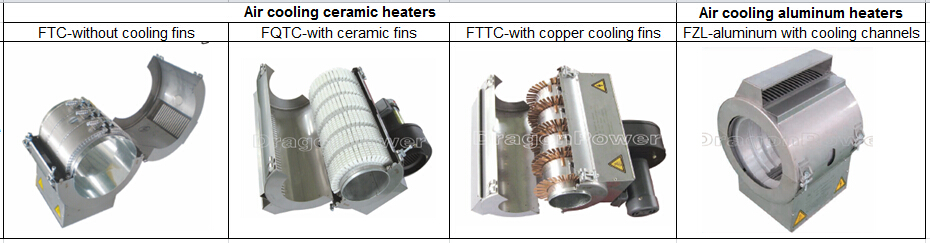

Air Cooling Ceramic Heater Description:

It is mainly used for complete extrusion parts. It consists of several heaters connected with temperature reducing systems. Depending on specific application requirements, the number and layout of this item can be combined into one system. As the extrusion cylinder is completely covered, it has a uniform temperature flow. Also due to the enlarged surface of heating radiation, the efficiency is improved. It can remove friction heat from extrusion. The air cooling ceramic heater with copper cooling fins consists of several band heaters. Then the set is covered by an individual mounted cooling jacket with a fan connection box and air outlet device fixed. In addition, the band heater can be removed and replaced. The maximum temperature the heater can stand is 500 ¡ãC. Currently, this heater is the most advanced cooling & heating device for extrusion machine and cylinder of injection plastic machine.

There are three models of air cooling heaters by DragonPower. Air cooling aluminum heater is another type.

For saving energy, insulation matt or cover can be used inside or outside of the heaters.

Air cooling heater Applications:

l Hollow shaping machine/Blow-molding machine

l Plastic injection moulding machine

l Extrusion machine/Co-extrusion line

l Raw material processing equipment

l Pelletizing equipment

l Granular machine

l All types of plastics processing machines

Packaging and Shipping

Packaging: air cooling heater without fins in plywood case outside if needed.

Shipment: 1.small quantity by DHL, FEDEX 2. Bulk goods by Sea Freight. 3. Arranged to your order

Our Service

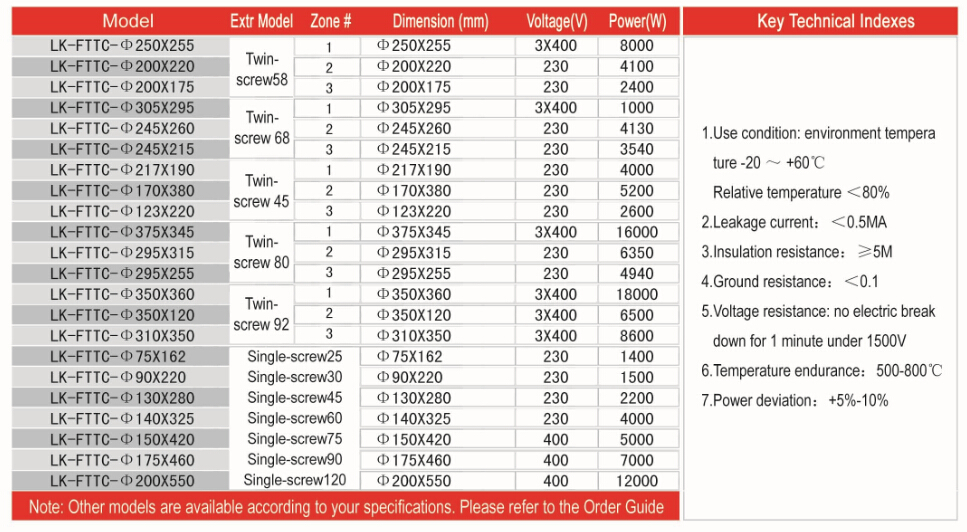

Air cooling heater order guide

Please specify the following when ordering.

1. The accurate inner diameter (mm) of heaters (specify the tolerance zone if applicable)

2. Voltage and power density

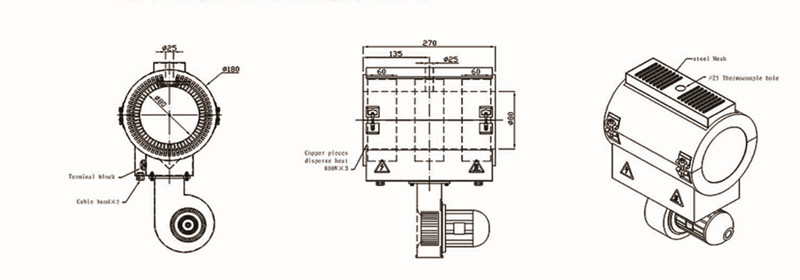

3. The position and size of the hole for connecting thermocouple OR of the incision.

4. Wiring type and position

5. Whether need air blowers

6. Content of the laser stamping on the sheath of heaters if needed

7. Order quantity

8. Delivery date

** It¡¯s better to provide us with the drawings/pictures

Others: position of terminal box, the position and size of the hole for connecting thermocouple OR of the incision, whether need to cast in the terminal

Certificates