Induction Heater Description:

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, where eddy currents are

generated within the metal and resistance leads to Joule heating of the metal. The induction coil itself does not get heated. The heat generating object

is the heated object itself.

DragonPower induction heaters got ISO9001,Rohs, CE certifications and patent for innovation with its latest technology to get energy saving up to 30%-80%.

|

Model |

Diameter (mm) |

Voltage(V) |

Power(W) |

Key Technical Indexes |

|

LK-DCGY-01 |

170 |

220 |

2000 |

1.Voltage: 220V-380V |

|

LK ¨CDCGY-02 |

230 |

220 |

2000 |

2.Power: 2-50KW |

|

LK ¨CDCGY-03 |

240 |

220 |

5000 |

3.Width of induction coils: 80-2000mm |

|

LK ¨CDCGY-04 |

260 |

380 |

5000 |

4.Current: 5A-75A |

|

LK ¨CDCGY-05 |

300 |

380 |

5000 |

5.Diameter of induction coils:¡Ý80mm |

|

LK ¨CDCGY-06 |

350 |

380 |

50000 |

6.MTBF(mean-time between failures:¡Ý10000 hours |

|

Note: Other models are available according to your specifications. Please refer to the Order Guide |

7.Work frequency: 10KHz-25KHz |

Features of Induction heaters:

1. Heating speed linked to the possibility of obtaining very high power density

2. Exact location of the heating effect thanks to the inductor design and an operating frequency perfectly adapted to the part to be heated

3. The possibility to heat at very high temperatures with an efficiency practically independent of the temperature

4. A process perfectly adapted to industrial medium-sized and mass production requirements

5. Easy automation of equipment,

6. Absence of thermal inertia (rapid start-up),

7. Repeatability of operations carried out,

8. Often extremely high heating efficiency,

9. Absence of pollution from the source of heating (cold source),

10.Good working conditions.

Induction Heater Applications:

1.Plastic Injection Molding Machines

2.Plastic Extruders

3. Oil Reclamation Equipment

4. Food and Candy Extruders

5. Drum Heating

6. Extrusion Dies

7. Holding Tanks

8. Blow Molding Machines

9. Food Service Warming

10. Hot Runner Molds

Application 1 - Blow Film Machine:

Application 2 - Blow Molding Machine:

Application 3 - Injection Molding Machine:

Application 4 - Cast Film Machine:

It¡¯s mainly applied in injection, extrusion, blow filming ,blow moulding ,wire drawing ,granulating and recycling machines etc. The product application includes film, sheet, profile ,raw material etc. It can be used for heating the barrel, flange, die head, screw and other parts of the machine with the advantage of 30-80% energy-saving rate.

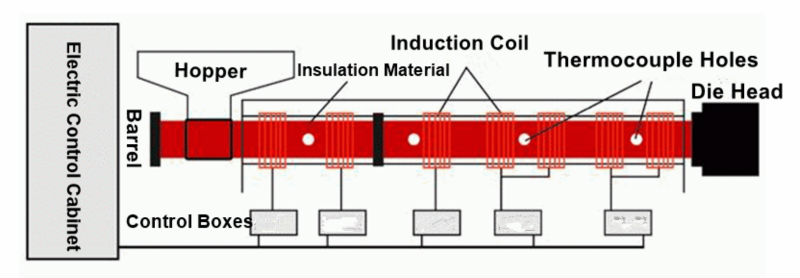

How does Induction Heater Work?

Induction Heater VS. Traditional Heaters?

|

Advantage Comparison |

|

Technical data |

Induction Heater VS. Traditional Heater |

|

Heating Principles |

Electromagnetic Induction |

Resistance wire heating |

|

Heated Part |

Induction coil itself is not heated but the barrel generates heat so the heat loss to environment is kept minimum. |

heater itself, then heat transferred to the heated object and so much heat loss to environment |

|

Surface Temperature & Safety |

Max.60¡æ on heater surface, safe to touch by hands. |

Above 200¡æ on surface and dangerous to touch |

|

Heating Rate |

High Efficiency: shorten 1/3 to 2/3 warming-up time |

Low Efficiency

Long time pre-heating |

|

Energy Saving |

Save 30-80% Power Consumption |

No Saving |

|

Temperature Control |

High precision |

Low Precision |

|

Using life |

3-4 years |

2-3 years |

|

Working Environment |

Cool down workshop temperature |

Hot, especially for low latitude Area |

|

Cost |

Cost-effective

30-80% energy-saving rate

It takes 6-10 months to recover the cost.

The higher the power capacity is, the higher energy-saving rate you get. |

Low |

Induct

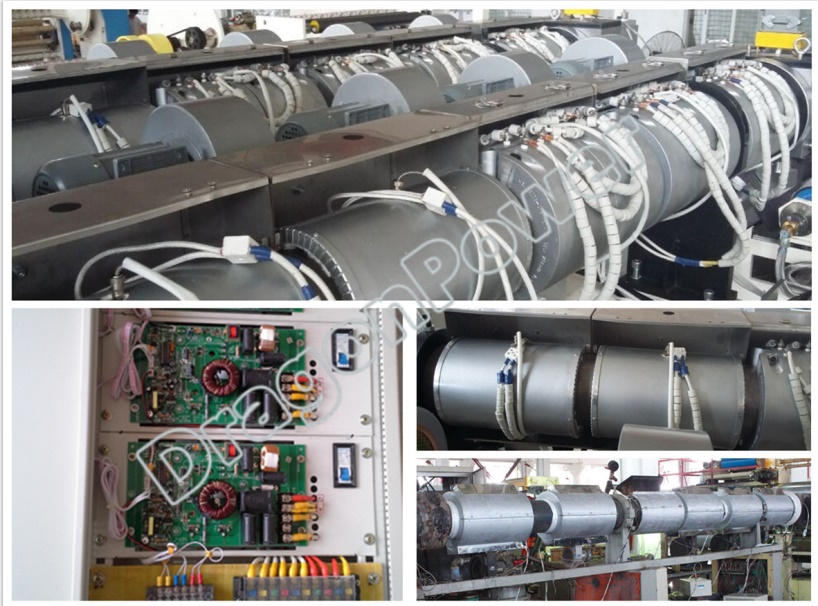

Induction Heater Photos:

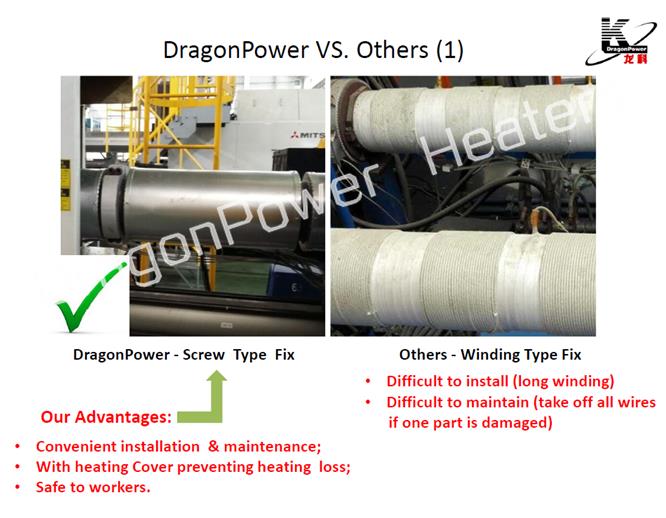

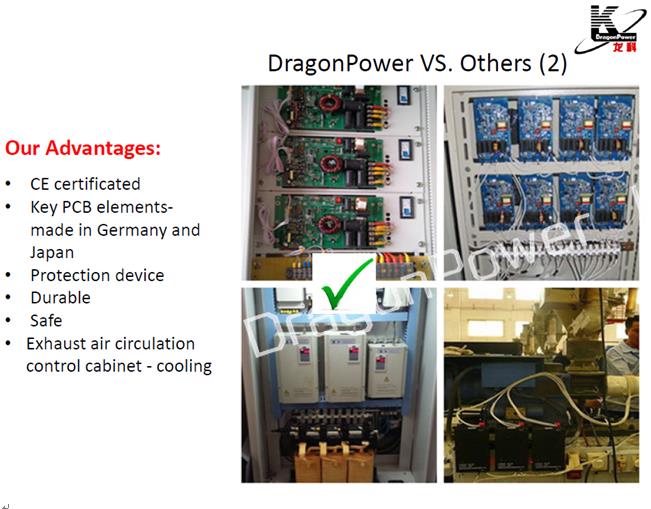

DragonPower Induction Heaters VS Others:

Packaging and Shipping of Induction Heaters:

Packaging: induction heater in plywood case outside if needed.

Shipment: 1.small quantity by DHL, FEDEX 2.Bulk goods by Sea Freight. 3. Arranged to your order

Our Service

Induction Heater Order Guide

Please specify the following when ordering.

1. The inner diameter (mm) and length (mm) of heaters

2. Thickness of heaters

3. Terminal length (max & min) and the distance of terminal length

4. The diameter, length of cooling tubes and the distance between them.

5. Voltage and power density

6. Gap of two pieces if applicable

7. Wiring type and position

8. Whether need air blowers

9. Content of the stamping if needed

10. Order quantity

11. Delivery date

** It¡¯s better to provide us with the drawings/pictures

Certificates